Competent Persons

All scaffolds must be erected, moved, dismantled or altered only under the supervision of a competent person

What is a “Competent Person”?

A competent person is able to:

identify existing and

predictable hazards

identify working conditions

that are unsanitary, hazardous

or dangerous and

has authority to eliminate hazards

Step 1: Preparation Consider the following:

What is the intended use?

what work tasks are involved

anticipated loads (materials & equipment)

how many people will be on it

unique building configurations

obstructions, such as electrical or piping

Step 1: Preparation Consider the following:

What are the site conditions?

debris to be cleared

uneven grade/slopes to consider

foundation type

soil conditions

concrete foundation

pavement/asphalt foundation

weather conditions

Step 1: Preparation

How high will the scaffold be?

will scaffold need to be secured or designed by a qualified person

What work will be performed on it?

welding or heat-producing tasks

how many people will be on the scaffold

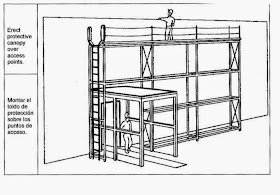

Will pedestrians be affected?

building accesses must be maintained

overhead protection may be required

Step 2: Proper Erection

Erect, alter, move, and dismantle under the supervision of a competent person!

Build to OSHA standards.

Use the appropriate fall protection system for the situation.

Step 3: Safe Use

Maximum Capacity

Inspection

Electrical clearances

Snow, ice, mud

Storms, high winds

Debris

Working level height

General Requirements

Scaffolds and their components shall be capable of supporting without failure at least four times the maximum intended load.

Nails or bolts used in the construction of scaffolds shall be of adequate size and in sufficient numbers at each connection to develop the designed strength of the scaffolds. Nails shall not be subjected to a straight pull and shall be driven full length.

All planking or platforms shall be overlapped (minimum 12 inches) or secured from movement.

Continued

An access ladder or equivalent safe access shall be provided.

Scaffold planks shall extend over their end supports not less than 6 inches nor more than 18 inches.

Employees shall not work on scaffolds during storms or high winds.

Tools, materials, and debris shall not be allowed to accumulate in quantities to cause hazard.

Working Conditions 1926.451

Debris shall not be allowed to accumulate on platforms.

scrap material

mortar

demolition materials

General Requirements

Wire or fiber rope used for scaffold suspension shall be capable of supporting at least six times the intended load.

OSHA has determined a 10 - foot fall protection for scaffolding.

Scaffolds cannot be erected, used, closer than 10 feet (3.1m) near energized power lines. (from 300 v to 50 kv).

OSHA requires that scaffolding must always be secure when height of the scaffold exceeds four (4) times the minimum base width.

Foundations/Sills:

Base plates must be placed under the legs.

Use mudsill continuous under both legs of the scaffold. The sill extends at least 9 inches past the center line of the leg and be of 2inch x 10 inches lumber.

Foundation Sills

Mud Sill Size

Most scaffolds 4 levels or less in height

|

2” x 10” pad,

12” - 18” long

|

Larger scaffolds on Type A Soil

|

2” x 10” pad,

18” long

|

Larger scaffolds on Type B Soil

|

18” square pads

|

Larger scaffolds on Type C Soil

|

36” square pads

|

Scaffold Foundations

Scaffolds must have base plates, even when setting on a concrete floor.

Also, the lack of a base plate could damage the scaffold leg.

Scaffold Support Examples

Inadequate support - in danger of collaps

Good support

Scaffold Foundations

Scaffold legs must be set on base plates and adequate mudsills.

There is no base plate and the scrap plywood is not adequate.

The scaffold frame could penetrate the plywood.

Never on Masonry!

Scaffolds should never be set on bricks, masonry blocks, etc.

These are not structural elements and could crush under the scaffold load.

Screw Jacks:

Screw jacks are used to level the scaffold.

Maximum extension is 18” in height.

Bracing:

The position and number of braces used on a scaffold not only restricts the amount of side movement, but also determines the strength of the scaffold.

Bracing at right angles to the building is achieved by the ties to the building and the inherent rigidity of the frame.

Special care should be taken with tube and coupler or systems scaffolds which need transverse bracing as well as ties.

Bracing

Bracing restricts the amount of side movement.

The normal interval is every lock spacing with frame scaffolds, and every 6.5 feet for tube and coupler or system scaffold

Ties:

It is essential that every scaffold be adequately tied to the building structure throughout its entire length and height. If not, collapse of the scaffold will occur.

The bottom tie must be placed no higher than four (4) times the minimum base width and every 26 feet vertically thereafter.

Horizontal ties will be at intervals not to exceed 30 feet.

At least 50% of ties should be positive.

Securing 1926.451(c)(ii)

If the base width is wider than 3’, the first tie will be a vertical distance of 4 times that (from the ground), and every 26’ thereafter.

Example:

base width = 5’

first vertical tie will be (5’ x 4) 20’ from the ground

Securing 1926.451(c)(ii)

Guys, ties, and braces shall be installed at each end of the scaffold and at horizontal intervals not to exceed 30’.

Types of Ties

Through Ties (+ ve)

Reveal Ties (- ve)

Box Ties (+ ve)

Anchor Bolt (+ ve)

Through Ties (+ve type):

A tube is taken through any convenient opening, such as a window, and coupled to a vertical or horizontal tubes

B- Reveal Ties (Not Positive):

A tube is wedged into an opening in the wall by means of reveal pin. A second tube is then fixed between this tube and the scaffold to form the tie.

C- Box Ties (Positive Ties):

If there are columns close to the scaffold. Tie tubes run both sides of the column, with cross tubes tied back and front to both tie tubes.

D- Anchor Bolt (Positive Type):

They leave a hole behind which has to be repaired.

A pull out force of at least 800 lbs, 1200 lbs, and 1600 lbs is necessary for light, medium, and heavy duty scaffolds respectively.

Planking

Wood scaffold planks should be nominal 2inches x 10 inches.

Planking should extend a minimum of 6 inches over the center of each support (unless cleated to prevent the plank from sliding) and a maximum of 12 inches

Planks

Wood scaffold planks should be nominal 2 inches x 10 inches. (actual 1.5” x 9¼”)

Planks should bear the stamp of a grading agency approved by the American Lumber Standards Committee)

The maximum span for wood planks should not exceed 8 feet. (platform shall not deflect more than 1/60 of the span when loaded.

Span of 8 feet for 25 pounds per square foot

Span of 6 feet rated for 50 pounds per square foot maximum.

Gaps between adjacent planks or toe boards should not exceed one (1) inch. (minimum width 18 inches)

platform

Must cover the entire platform

Platforms/Decking

Platforms/Decking

Each end of the platform, unless cleated or restrained by hooks or equivalent means, shall extend over the centerline of its support at least 6”.

Platforms/Decking

Where platforms overlap to create a long platform, the overlap shall occur only over supports, and shall not be less than 12” unless nailed together.

No large gaps in front edge of platforms

Each abutted end of plank must rest on a separate support surface

Overlap platforms at least 12 inches over supports, unless restrained to prevent movement

Each scaffold walkway shall be at least 18 inches (45 cm) wide.

Planks

Always plank out the full width of the scaffold. (the minimum plank width is 18 inches)

Checking of Scaffold Boards (A board should not be used if:

Either end is split sufficient to cause a weakness.

It is damaged by fracture or saw cut, is splintered, has been nailed, or concrete or plaster is sticking to it.

It has had oil, corrosive liquid or acid split on it.

It has any part painted (which may cover up a weakness)

It is excessively warped, or if any part is decayed.

Platforms/Decking

platform shall not be more than 14” from the face of the work unless fall protection is provided.

Capacity

4 times the intended load + scaffold weight

Planks must not deflect more than 1/60 of span when loaded

Maximum Capacity 1926.451(f)(16)

Platforms shall not deflect more than 1/60 of the span when loaded.

Example: span = 10’ ( or 120” )

120”/60 = 2” maximum deflection (or bowing of the board under the weight)

Good rules and requeriments to implement in our work and avoid all the accidents we could have with the aluminum scaffolding, thanks!

ReplyDeleteGreetings. I know this is somewhat off-topic, but I was wondering if you knew where I could get a captcha plugin for my comment form? I’m using the same blog platform like yours, and I’m having difficulty finding one? Thanks a lot.

ReplyDeleteindustrial safety course in chennai

Here is Mr Benjamin contact Email details,lfdsloans@outlook.com. / lfdsloans@lemeridianfds.com Or Whatsapp +1 989-394-3740 that helped me with loan of 90,000.00 Euros to startup my business and I'm very grateful,It was really hard on me here trying to make a way as a single mother things hasn't be easy with me but with the help of Le_Meridian put smile on my face as i watch my business growing stronger and expanding as well.I know you may surprise why me putting things like this here but i really have to express my gratitude so anyone seeking for financial help or going through hardship with there business or want to startup business project can see to this and have hope of getting out of the hardship..Thank You.

ReplyDeleteThanks for the amazing information..Excellent post.

ReplyDeleteGreat blog on scaffolding rules! For affordable and safe scaffolding rental in rajkot, I recommend checking out Amirsons.

ReplyDelete